Fiberglass Gelcoat Restoration

and Boat Graphics

Back to

Completed Projects Back to Technical

Tips Home

What a Dull Looking Finish . . . A 17 year old boat usually loses much of its original

Gelcoat shine. This was the case with my boat, and no matter how

much wax/polish I applied, the finish still looked pretty dull.

The boat would not repel water and would easily become stained.

To correct this problem (i.e. restore the shine), there are a

number of ways you can go . . .

What a Dull Looking Finish . . . A 17 year old boat usually loses much of its original

Gelcoat shine. This was the case with my boat, and no matter how

much wax/polish I applied, the finish still looked pretty dull.

The boat would not repel water and would easily become stained.

To correct this problem (i.e. restore the shine), there are a

number of ways you can go . . .

- Rubbing Compond and lots of rubbing

- AwlGrip (or similar) coatings

- Professional re-finishing

- Co-Polymer Restoring Products

The

lowest cost and least effort is the Co-Polymer Products

(PoliGlow, VertGlas, etc.). This is the route I chose to go, and

after checking some product reviews, purchased a restoring kit

from the makers of "PoliGlow" www.poliglowproducts.com . The kit includes everything needed to prep and

restore the fiberglass surface of a 25 foot boat. I did a small

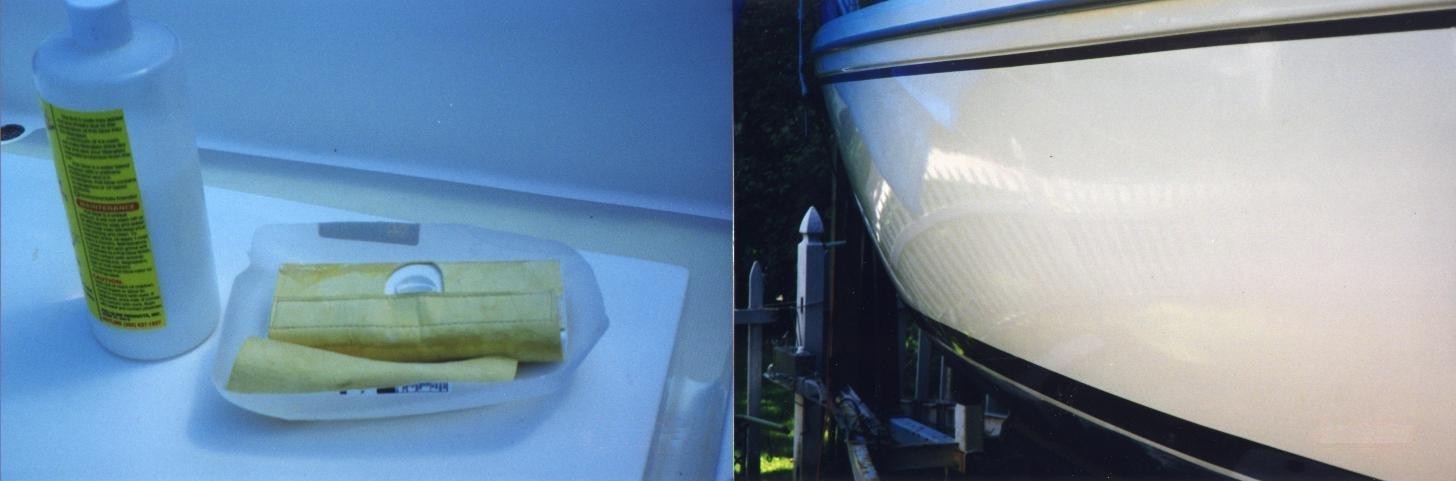

area to test the product out. You can see in the image to the

left the difference in reflection between a treated and an

untreated area (red arrows mark the boundary).

The

lowest cost and least effort is the Co-Polymer Products

(PoliGlow, VertGlas, etc.). This is the route I chose to go, and

after checking some product reviews, purchased a restoring kit

from the makers of "PoliGlow" www.poliglowproducts.com . The kit includes everything needed to prep and

restore the fiberglass surface of a 25 foot boat. I did a small

area to test the product out. You can see in the image to the

left the difference in reflection between a treated and an

untreated area (red arrows mark the boundary).

I spent quite a bit of time cleaning and

preparing the surface for re-finishing. The PoliGlow will lock in

any stains, discolorations, etc. Therefore, it is important to

get the boat really clean - a mild bleach/water solution works

wonders. There were a couple of discolored areas that even bleach

would not clean. I sanded these areas lightly with 600 grit

sandpaper.

Once the boat was clean, it was time to apply

the special oxidation removing agent supplied in the restoration

kit. At this point, I realized that I needed to cover the boat,

as it was quickly getting dirty from dust in the air and the

trees in the yard. I used the mast as a supporting beam and

draped a tarp over the boat. This gave protection from the trees

and allowed adequate space to work.

|

| Pictures of tarp

set-up and work area. |

Give It A Shine . . . The hull was

in pretty good shape already; the really bad areas were topside

(due to sun exposure over the years). I prepared to coat the

topside surfaces, then coat the hull. I contemplated the non-skid

areas, and finally decided to give them a single coat as a

compromise between 'non-skid' and 'stain resistance'. The other

areas of the deck, cockpit and cabin top received 4-5 coats. I

took off the Pop-Top Assembly and the Cockpit Locker Hatches and

coated them separately. This allowed me to treat the entire deck,

cabin top, and hull without dealing with extraneous pieces. There

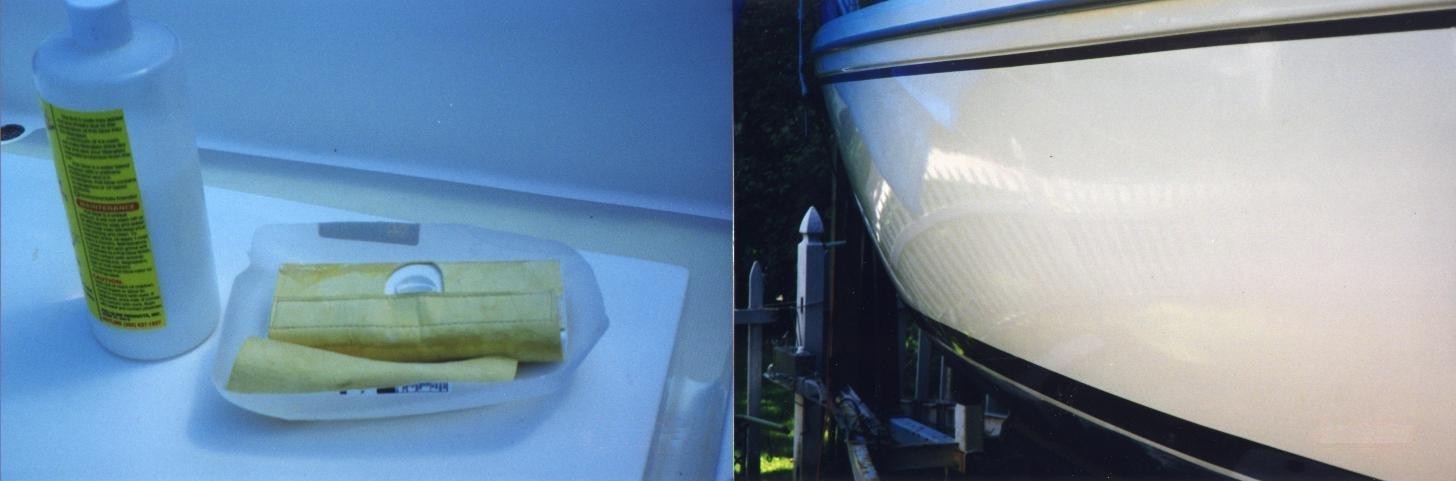

were two application cloths provided in the kit (looked like

Chamois); one for large areas and the other for small areas. I

made a shallow tray out of the side of a milk carton, which

allowed me to soak the application cloths and not drip any

solution on the ground. I was concerned if there was enough

solution to do the entire boat, but only used about 2/3 of the

solution provided in the kit (1 Quart).

|

| Picture of the

"tools of the trade" and the final results. |

As you can see by the reflection in the picture

above, the results are quite astounding. I was very pleased with

the results and the durability of the shine. People tell me that

it looks like a new boat.

Now for a Name . . . Now that the PoliGlow had been applied to the hull, I

could apply the graphic lettering in order to 'officially' give

my boat a name. Giving a boat a name can be quite ceremonial;

there are several boat naming ceremonies you can find on the web.

Some are for the original naming and some are for re-naming. The

previous owner of my boat did not give it a name. So as far as I

know, this is the first name the boat has been given.

I thought about a name for the boat and asked

the family for suggestions. Then, finally, a name came to me that

epitomized the meaning of the boat (to me) -

"Essentials" .

I ordered a set of graphic lettering from

Boat/US - using my handy member discount, of course. The

lettering came within a few days. After reading the instructions

through several times, I was ready to apply the graphic

lettering. I ordered lettering with a 'Drop Shadow' effect, so

there was actually two sets of lettering - one for the Drop

Shadow, and the other for the main lettering.

|

| The two-step process

of adhering the letters to the hull. First the shadow effect (left), then the main

lettering ( Right)

|

It helps to have the boat level while setting

up the graphic lettering, as it is easier to get the lettering

level with the water line. I used masking tape to denote the

baseline and temporarily hold the backing material in place while

the letters set-up/dried.

The Final Results

|

| The final results of

the graphic lettering, and the boat all dressed up and

ready to go. |

Poli-Glow: How Long Does it

Last ? (you ask) . . .

I applied the Poli-Glow in 1999

and it has been on for 4 seasons at this point (2003). I have not

polished the boat since then. It is looking like it could use a

re-coat after four years - pretty good! Perhaps I will shine it

back up for the 2004 season.

Back to

Completed Projects Back to Technical

Tips Home

What a Dull Looking Finish . . . A 17 year old boat usually loses much of its original

Gelcoat shine. This was the case with my boat, and no matter how

much wax/polish I applied, the finish still looked pretty dull.

The boat would not repel water and would easily become stained.

To correct this problem (i.e. restore the shine), there are a

number of ways you can go . . .

What a Dull Looking Finish . . . A 17 year old boat usually loses much of its original

Gelcoat shine. This was the case with my boat, and no matter how

much wax/polish I applied, the finish still looked pretty dull.

The boat would not repel water and would easily become stained.

To correct this problem (i.e. restore the shine), there are a

number of ways you can go . . . The

lowest cost and least effort is the Co-Polymer Products

(PoliGlow, VertGlas, etc.). This is the route I chose to go, and

after checking some product reviews, purchased a restoring kit

from the makers of "PoliGlow"

The

lowest cost and least effort is the Co-Polymer Products

(PoliGlow, VertGlas, etc.). This is the route I chose to go, and

after checking some product reviews, purchased a restoring kit

from the makers of "PoliGlow"