Sea Trial and Survey

I hired a surveyor that worked both the MA and NH areas, and also did both vessel and engine surveys, which is a rare find. This made things very cost effective. The survey started out with a sea trial, then we proceeded to the travel lift to take the boat out of the water for an inspection of the hull, the outdrives and other underwater components. The balance of the survey was completed with the boat back in the water and finished with a compression test of the engines.

Below are a few pictures of the day as well as a video of the inspections, etc.

There were a few significant issues identified during the survey . . .

The exhaust manifolds were shot . . . the starboard fuel pump was leaking . . . the hull had some blisters starting to form.

There were a host of other things, typical for a boat of its age, that would need to be addressed over time. The seller and I worked out an agreement to address the more critical issues. So, the deal was going forward.

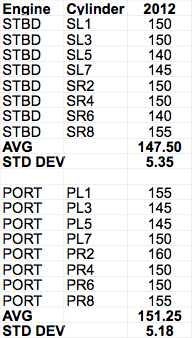

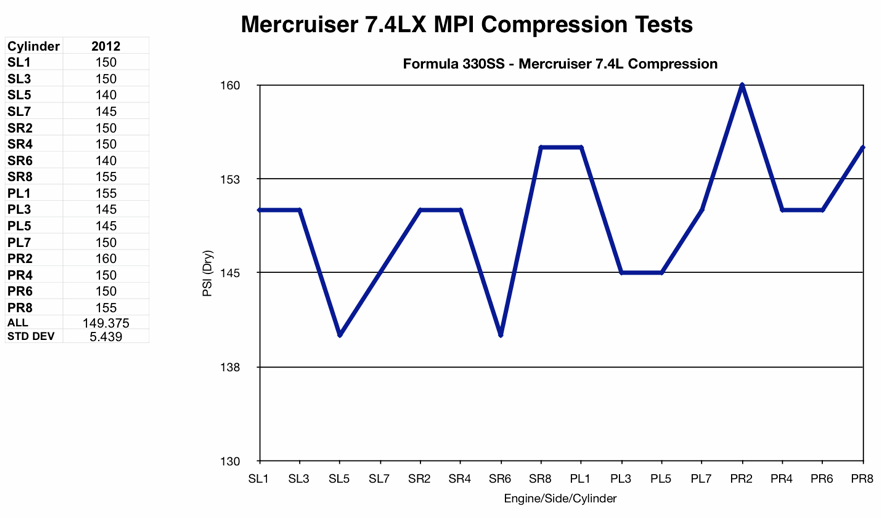

The compression tests on the engines came out OK, I graphed out the results as shown in the picture below. I typically do a compression test (and even a leak test) every year, just to see if there are any significant changes year-to-year. You can see from the graph that the port engine is a bit stronger than the starboard engine.

Below are the compression test numbers, averages and Std. Deviation for each engine separately,

To the right is a YouTube video of the survey day . . .

Now it was a matter of waiting for the seller to complete the agreed repair from the survey, while I lined up a transportation company to retrieve the boat and deliver it to its new home.