Outdrives

Here is a closer view of the propeller shaft hub area and the corrosion that had occurred (left). This area is closest to the stainless steel propellers and usually suffers the most from inadequate protection against galvanic corrosion.

For some prospective buyers, these outdrives might have been a major concern, but for me, they actually were in better condition than the outdrive on my 242, which suffered from some amount of time in salt water without proper corrosion protection, prior to my ownership.

My plan was to grind the corrosion areas with my high speed wire wheel and then do a full paint job on the outdrives. I also planned to add the extra anodes, as there are some retrofit kits available. As a final step, the outdrives need anti-fouling paint to protect them from marine growth.

I suppose that I should also change the gear oil as well.

The outdrives were original to the boat and in need of a little bit of care; mostly from a corrosion perspective. These outdrives were used in fresh water for 16 years, and that is generally a good thing. However, the early model Bravo III outdrives had some corrosion issues, due to the greater amount of stainless steel on the outdrive, in the form of the dual propellers. The extra amount of stainless steel tended to be too much for the anodes provided. Later year Bravo III outdrives added 2 additional anodes to remedy the corrosion problems.

To compound matters a bit, it appeared that the anodes on the outdrives had not been changed in a couple of years. This is often a misconception with fresh water use, that the anodes do not have to get changed as often. The problem lies in that even though the metal anode does not get depleted nearly as much in fresh water versus salt water, the electrical conductivity becomes diminished year-to-year, even with a small amount of depletion. So, left alone, the anodes loose their effectivity in the second and third year of use, if kept that long. So, during the survey it was noted that these outdrives would need some attention and additional anodes in preparation for going into the salt water.

Below are some pictures of removing the outdrives and painting them in preparation for next season.

Quick Links:

Back to Home Page

Here are a few pictures of the port outdrive as it is having the corrosion ground off with the high speed wire wheel. It takes the paint and loose metal off with minimal effort . . . just don’t get any body parts in the way of it. . . .

I read about some folks using Cold Galvanizing Compound on stainless steel props as a barnacle inhibitor. I though that since it is mostly zinc, it might be good to use as well for galvanic corrosion protection. So, along with the zinc chromate outdrive primer and some black enamel paint, I got some of the CGC for the propellers. We shall se how it works out.

Below are some pictures of the paint supplies, the props painted and the outdrives ready for primer.

Back to Maintenance Page

Here is a picture (left) of the Zinc Chromate Primer painted on the outdrives. Below are the outdrive re-installed and painted.

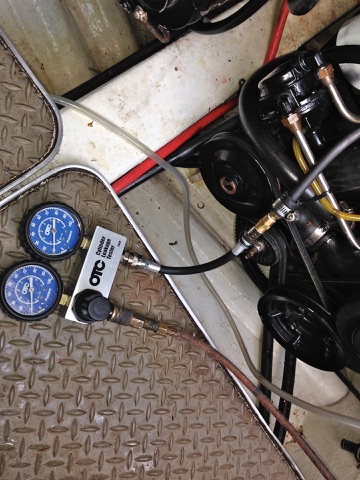

Pressure Testing